Traction plays a key role in every successful sewer inspection. If your system’s wheels are slipping along the pipe, you are losing traction, and therefore not getting the maximum potential out of your inspection and rehabilitation equipment. There could be a few reasons why you are losing traction in the pipe:

- Wheels are old and need replacing. We put our systems through some of the nastiest conditions imaginable, which leads to typical wear and tear, and eventually replacing. IBAK’s standard wheels are designed to be easily interchangeable and are inexpensive for this reason!

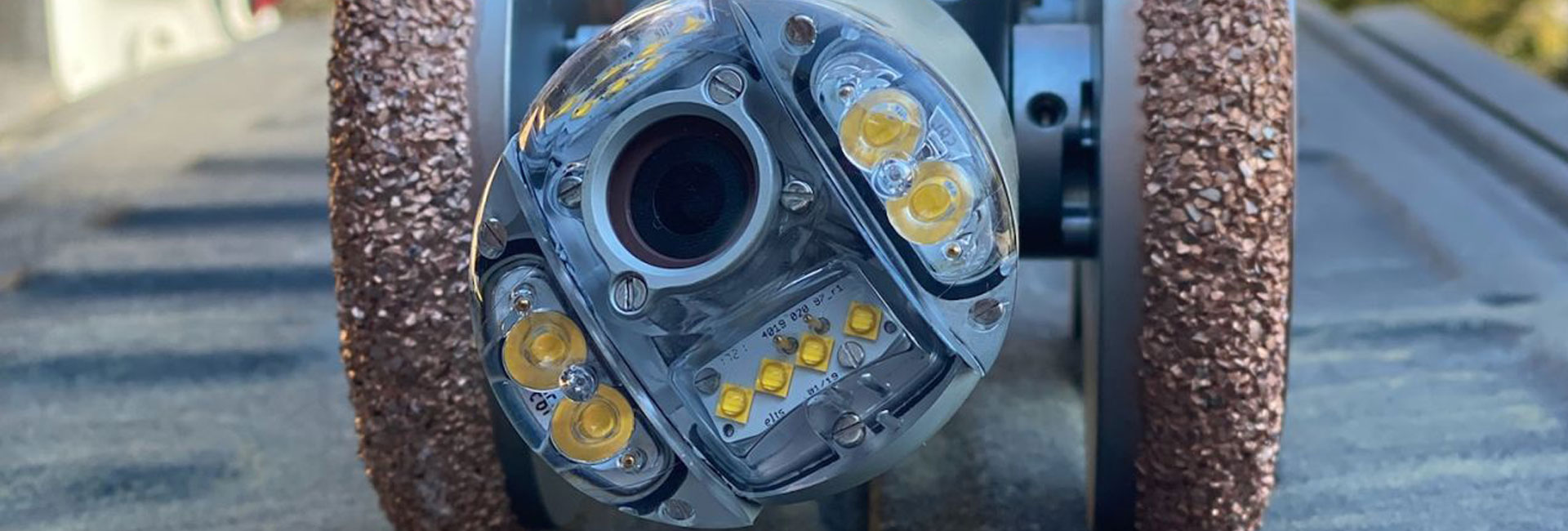

- Not using the correct wheels for the pipe conditions. Most manufacturers offer many types of wheels to be used in specific situations. For example, IBAK produces 4 different types of wheels other than their standard rubber wheels. These include pneumatic tires, high-traction tungsten carbide wheels, treaded wheels, and granulated wheels. Click on a wheelset to learn more about their specific use cases.

- Inspection system is too light and needs additional weight. One of the easiest ways to increase your traction in the pipe is by adding weight. IBAK offers additional weight kits and other additional accessories to help achieve this. In the video below, Matt Sutton, V.P. of Sales & Marketing at RapidView, does a great job of explaining this concept.

The Physics: Weight = Traction = Distance

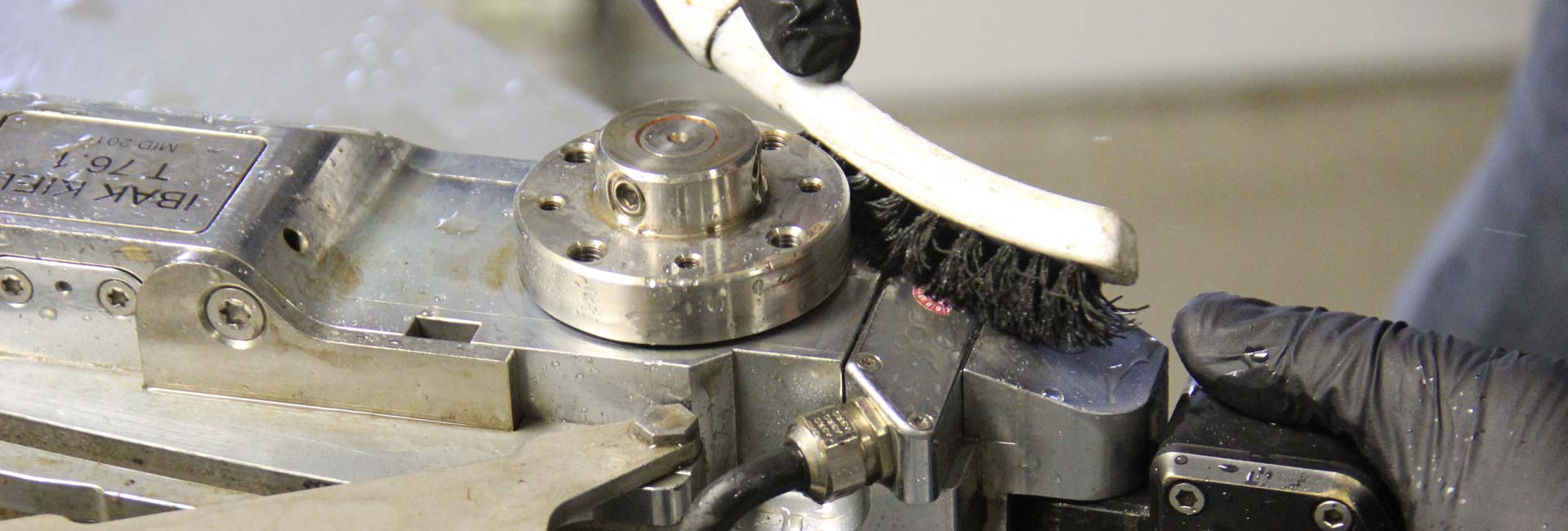

Why should a sewer inspection system be heavy? It comes down to simple physics; traction is only achieved by friction between the contact surface (wheel) and the pipe wall. Manufacturers like IBAK, build their camera tractor robots out of dense materials like brass. The additional weight creates more downward force on the wheels, in turn, creating more friction between the wheel and pipe. The traction that you gain from the added weight will provide longer distances through slippery lines and maximize efficiency.