The Importance of Maintaining Your Equipment

In the demanding field of underground inspection and rehabilitation, availability is your system’s best ability. Repairs cost money, and downtime eats into potential profits, so keeping up with proper maintenance and general knowledge of your system is one thing the operator can control. Like any complex tool, ignoring proper care can significantly decrease the lifespan of your investment.

Our North-Central Sales Territory Manager, Andy Melton, has over two decades of experience in the pipeline inspection industry. In his experience, he has identified four critical rules that operators can follow to not only be more successful with their system but maximize the lifespan.

1. Read Your Owner’s Manual

It is recommended that you read your owner’s manual from front to back before operating your system. While this sounds straightforward, a surprising number of confident operators are willing to get their hands on the controls before reading the manual.

The truth is, the owner’s manual is written by the manufacturer’s engineering team and contains valuable information. For example, most operator manuals include charts and diagrams for specific setups depending on conditions. Rather than scrambling to find the answer when an issue occurs, this information is much more valuable to know beforehand. It may be trivial, but having general knowledge of the manual allows for quick and easy references when needed.

2. Go Slow to Go Fast

Slow and steady wins the race when it comes to protecting your equipment. During an inspection, the goal is always to be efficient, but hurrying can lead to costly mistakes.

- Always be cautious when lowering/raising the unit in and out of the manhole. This is where the most damage can occur.

- There are many distractions during this phase, such as traffic and weather conditions, which can lead to accidents like the system hitting the side of the manhole or being dropped.

- Once the system is in the pipe and the inspection is underway, the same rule applies.

- Of course, you want to inspect quickly, but do not sacrifice missing crucial defects and observations. Slowing down and paying close attention will save you time and money down the road.

3. Protect Your Cable

The most important component in every CCTV inspection system is its cable. Damaged cables commonly require expensive reterminations or even complete replacement. There are a few key things you can do to prevent damage:

- Use rollers: If your cable is making contact at the top of the manhole, use a manhole top roller. A down-hole roller at the bottom is also recommended.

- Positioning your vehicle: Park your truck or vehicle at a reasonable distance from the manhole and ensure it is in line (or as close as possible given the conditions).

- Choose a manufacturer with a dual-axis cable connection: This allows the cable to move freely and prevents frequent bends and pinches.

Spending a little extra time on the setup to reduce friction on your cable will pay dividends in the years to come.

4. Clean Your Equipment

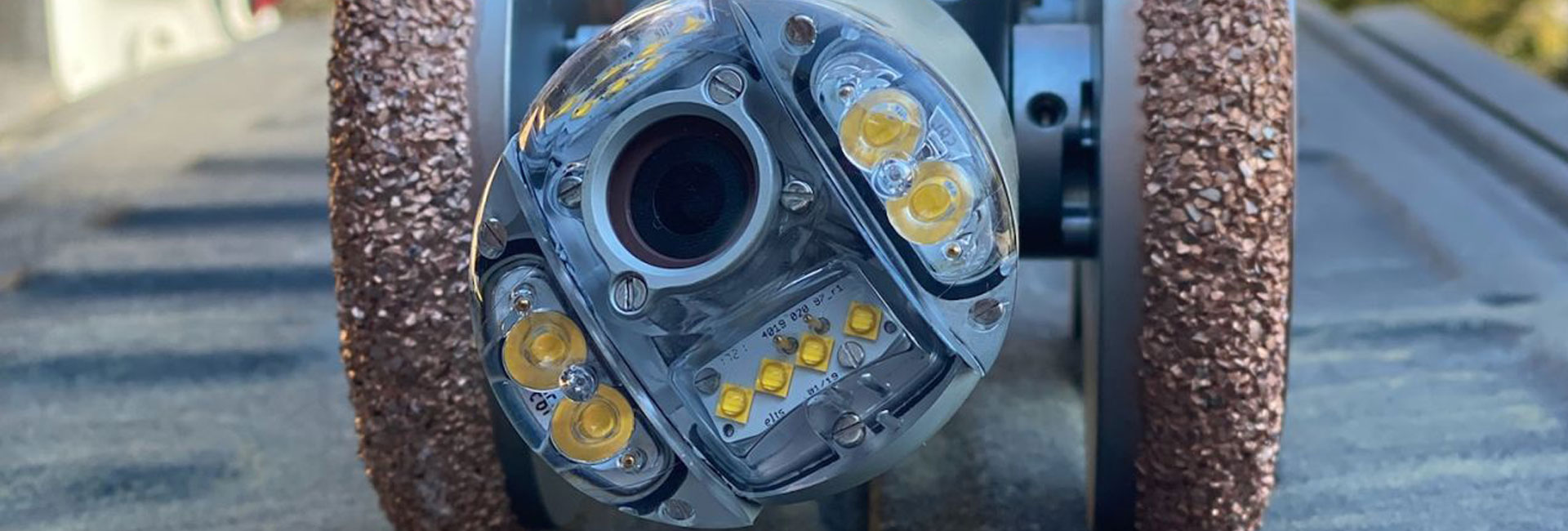

Pipe inspection and rehabilitation robots are not simple tools. They are mechanical and electronic systems that operate in some of the worst environments possible. Over time, debris can accumulate around continuously moving parts such as wheel seals, pan & tilt camera surfaces, and other articulating parts.

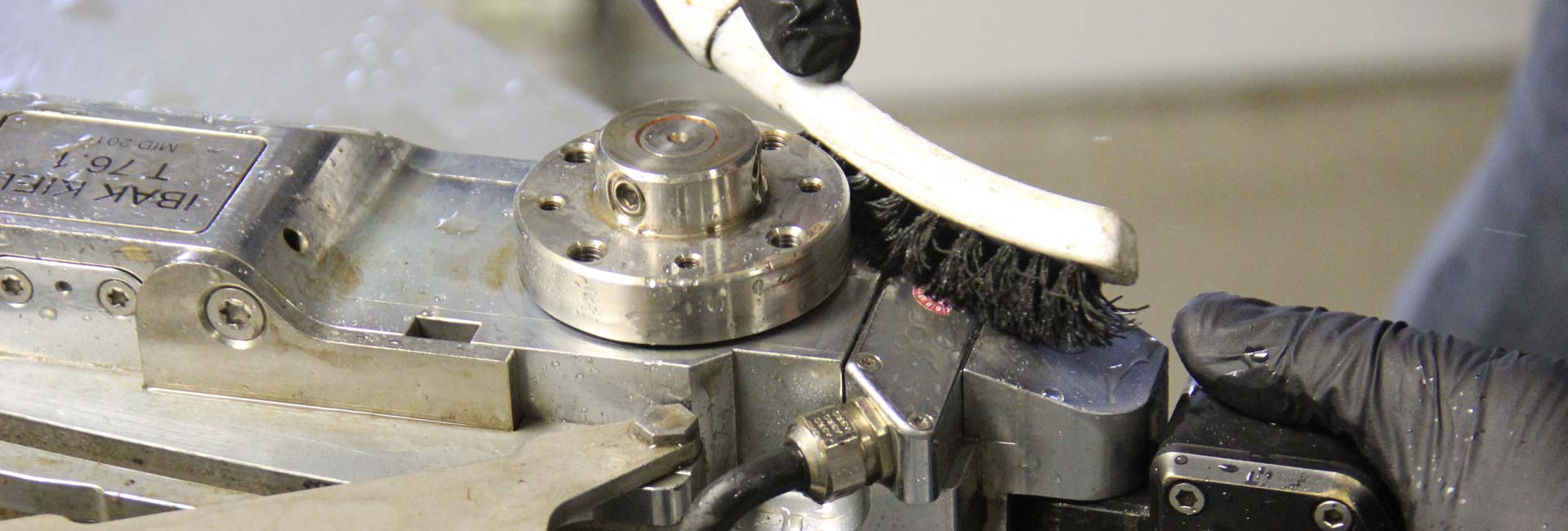

Typically, your manufacturer should provide a recommended process for cleaning your equipment, but here are some general guidelines:

- Always use appropriate PPE.

- Immediately rinse your system with water upon raising it out of the manhole.

- Avoid high-pressure water. Water from a hose or faucet is sufficient if done on a regular basis.

- Use dish soap and water. Harsh cleaning chemicals are not necessary.

- Use a soft brush to get into hard-to-reach areas that require attention.

Final Thoughts

While these four rules may sound obvious, they shouldn’t be overlooked. Following these general guidelines will not only increase profits but, most importantly, reduce downtime and repairs while extending the lifespan of your investment.

Originally published in Trenchless Technology magazine. Read the original article here.