The Importance of Maintaining Your Pipeline Inspection Equipment

After servicing pipeline inspection equipment for decades, one of the most common causes of long-term damage is dirty, poorly maintained equipment. Contractors and municipalities invest in high-quality inspection equipment, and without proper care, they are not getting the full lifespan out of their inspection system.

Why Maintenance Matters

Pipeline inspection robots are not simple tools. They are complex mechanical and electronic systems that operate in some of the harshest environments. Over time, debris can accumulate around continuously moving parts such as:

- Wheel seals

- Elevators

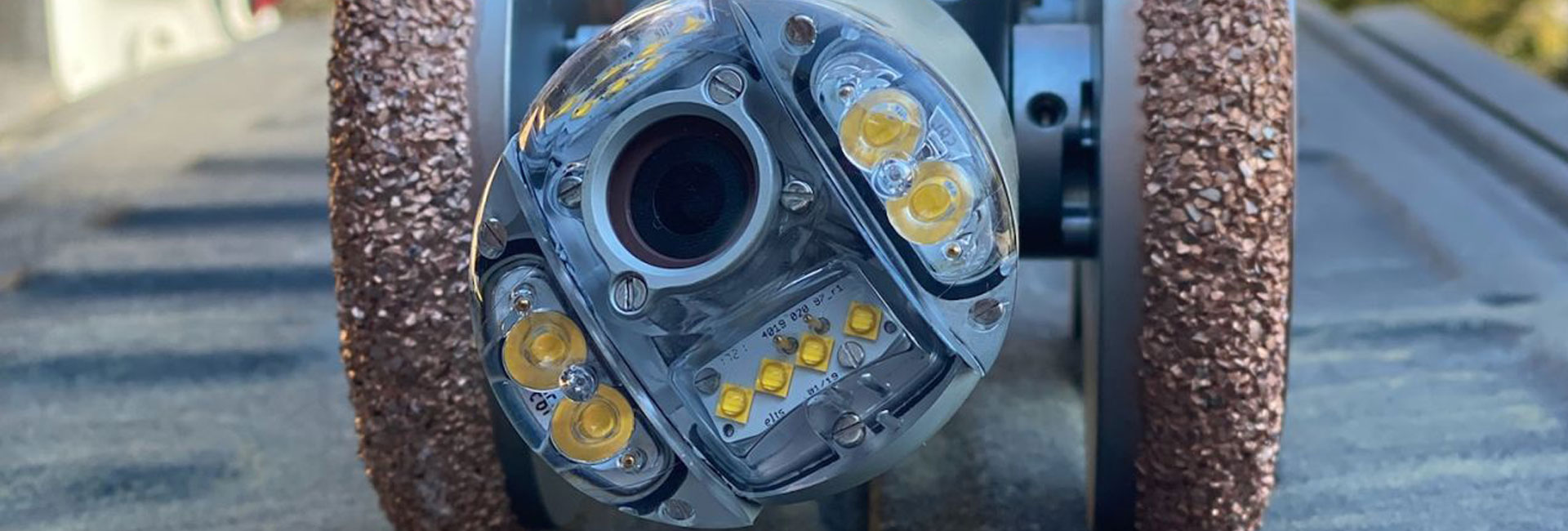

- Pan-and-tilt camera surfaces

- Other articulating parts

Most manufacturers use corrosion-resistant materials to construct their equipment. However, even with these materials, a small amount of friction from loose debris can still cause flaws in your system. Proper maintenance can prevent costly damage and extend the life of your equipment.

Cleaning Your Pipe Inspection System

Your camera manufacturer should provide a recommended process for cleaning and maintaining your equipment. However, here are some general best practices:

1. Always Use Appropriate PPE

Ensure you are wearing proper protective gear while cleaning your equipment to avoid injury and contamination.

2. Rinse Your System Immediately After Use

- Upon removal from the sewer system, immediately rinse your system with water.

- Wash any loose debris back down the manhole to prevent buildup.

- If debris accumulates over time, it becomes harder to remove, leading to performance issues.

3. Avoid High-Pressure Water and Harsh Solvents

- Do not use high-pressure water, high-pressure air, or solvents that could damage delicate components.

- Water from a hose or faucet is typically sufficient if done regularly.

4. Focus on Articulating and Moving Parts

- Pay close attention to wheels, lifts, and cameras.

- These areas need to remain clean to ensure all key components function properly.

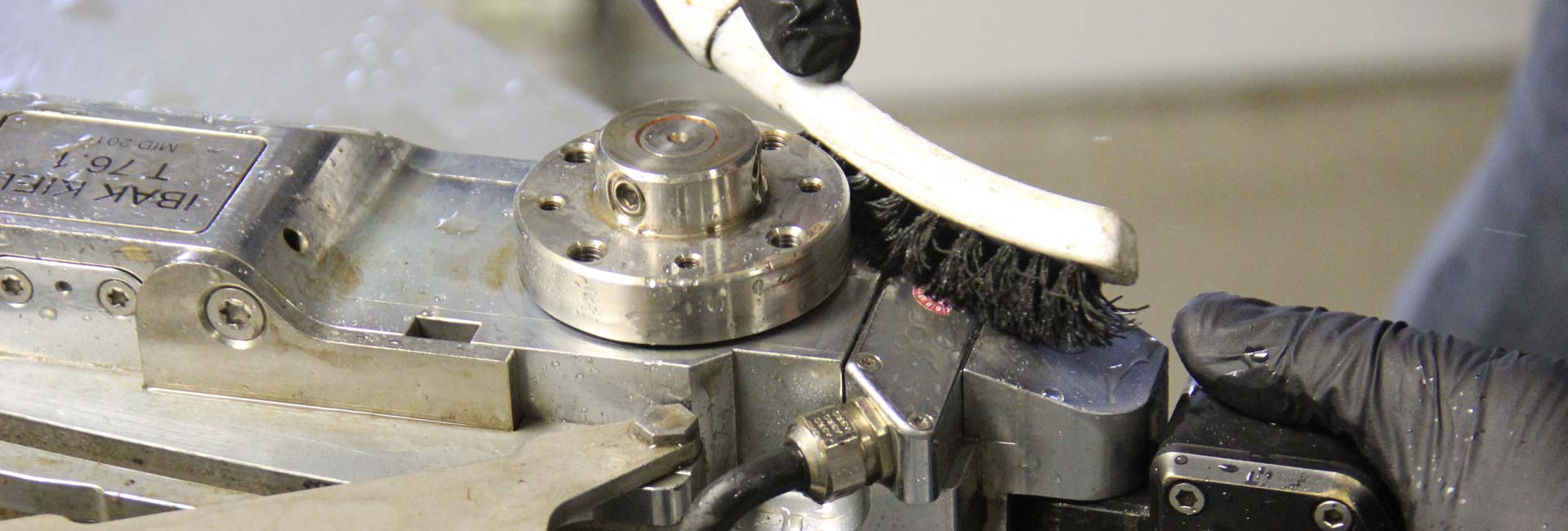

5. Perform Thorough Cleaning on a Schedule

- Set a schedule to conduct a deep clean at least once a month.

- It is recommended to clean your system every few weeks.

- Use a soft brush to get into hard-to-reach areas, similar to detailing a vehicle.

The Long-Term Benefits of Proper Maintenance

No matter how busy your schedule is, taking time to maintain your inspection and rehabilitation equipment is always worth it. Neglecting maintenance can lead to:

- Unnecessary downtime

- Reduced profitability

- Damage to your professional image

By following these simple cleaning and maintenance practices, you can extend the lifespan of your equipment, improve efficiency, and reduce costly repairs.